3-A Sanitary Standards

The 3A Sanitary Standards primarily exist to prevent contamination and ensure that all equipment parts and surfaces can be effectively cleaned. 3-A Sanitary Standards play a crucial role in safeguarding consumable products by establishing rigorous guidelines that ensure processing equipment is free from foreign matter. These standards provide a framework for healthy and safe food production by emphasizing the importance of high-quality equipment. By adhering to these standards, manufacturers can significantly reduce the risk of contamination, thereby securing a critical component of the food supply chain.

Ensuring Cleanable Equipment

Cleanliness in food processing goes beyond everyday standards, requiring the elimination and prevention of dangerous bacteria and other impurities from all equipment involved in the manufacturing process. The aim is not just to maintain an appealing appearance but to ensure that equipment can be thoroughly cleaned to prevent any harm to consumers. This involves both mechanical and manual cleaning processes.

3-A Sanitary Standards are essential because they ensure that equipment can be fully cleaned, whether through automated systems or manual methods. By adhering to these guidelines, manufacturers can maintain high hygiene standards and protect consumer health.

Common FAQs

3A Standards are a set of sanitary guidelines established by regulators, equipment manufacturers, and processors to ensure the design and fabrication of equipment used in food, beverage, and pharmaceutical industries meet stringent hygiene and safety requirements. These standards promote cleanability, ensuring the materials used are safe for food contact, and preventing contamination by specifying how equipment should be designed for easy cleaning and inspection.

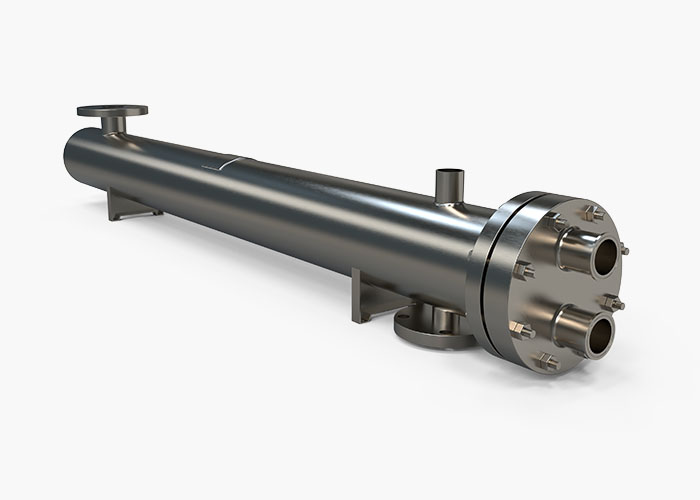

The goal of 3A Standards is to ensure equipment like pumps, vessels, valves, and heat exchangers, used in the production process, can be easily sanitized to maintain product safety and quality. These standards are widely recognized in industries requiring high levels of sanitation, such as dairy, food processing, and biotechnology. 3A standards are overseen by 3-A Sanitary Standards Inc., an independent entity focused on improving the sanitary design of equipment used in the food and beverage industry.

The 3A certification process involves some steps to ensure equipment used in the food, beverage, and pharmaceutical industries meets rigorous sanitary standards. Here's how it works:

- Application: Manufacturers submit an application with equipment drawings and specifications.

- Third-Party Evaluation: A certified inspector reviews the equipment for compliance with 3A Standards.

- Testing & Inspection: The inspector verifies cleanability, material use, and design integrity.

- Certification: Upon passing, the manufacturer receives 3A certification and can display the 3A symbol.

- Ongoing Compliance: Periodic re-inspections ensure continued adherence to 3A Standards.

3A accepted practices are guidelines developed by 3-A Sanitary Standards, Inc.

to ensure the processes and procedures used in food, beverage, and pharmaceutical production promote sanitary conditions and food safety. While 3A Standards focus on the design and construction of equipment, 3A Accepted Practices provide best practices for the operation, maintenance, and cleaning of equipment.

These practices outline procedures for proper handling, cleaning, and sanitizing to prevent contamination and ensure equipment remains compliant with hygiene standards throughout its use. They are critical for maintaining consistent sanitation in production environments, and ensuring food and beverage products are safe for consumption.

3A approval ensures equipment is constructed with materials and designs to promote cleanliness, are easy to sanitize, and prevent contamination, making them suitable for hygienic processing environments. Once a piece of equipment passes inspection by an independent third party, it receives 3A Approval, allowing the manufacturer to display the 3A symbol. This mark assures buyers and regulatory bodies the equipment meets high standards for food safety and sanitation.

The 3A Sanitary Standard 18-03 is a set of guidelines established by 3-A Sanitary Standards, Inc. for the design, fabrication, and cleanability of multiple-use plastic materials used as product contact surfaces in dairy and other food processing equipment. This standard ensures plastic components like seals, gaskets, and other parts in direct contact with food products, meet strict hygiene and safety requirements.

The standard specifies criteria for the material's resistance to wear, its ability to withstand cleaning and sanitizing processes, and its suitability for use in environments where food safety is important. By adhering to 3A Sanitary Standard 18-03, manufacturers ensure their plastic components prevent contamination and contribute to the overall cleanliness of the equipment.

The 3-A Specifications ensure equipment used in the food, beverage, and pharmaceutical industries is designed to be easily cleaned, prevents contamination, and uses safe materials that comply with food safety regulations. The 3-A Specification covers a range of equipment and promotes high hygiene levels in processing environments. Equipment that meets 3-A Specifications is eligible for 3-A certification, which signifies compliance with these rigorous standards and assures manufacturers, regulators, and consumers of its sanitary quality.

The USDA 3-A Standard refers to sanitary standards jointly developed by the USDA and 3-A Sanitary Standards, Inc. for equipment used in dairy and food processing industries. The 3-A Standards ensure equipment is safe for food contact and can be thoroughly sanitized. While the USDA oversees food safety regulations, 3-A Sanitary Standards focus specifically on equipment used in food production.

In the food industry, the goal of 3A standards is to ensure equipment is easy to clean, made from safe materials and minimizes the risk of bacterial contamination. Compliance with 3A standards helps manufacturers maintain high levels of cleanliness, meet regulatory requirements, and produce safe, high-quality food products.

Related Links: