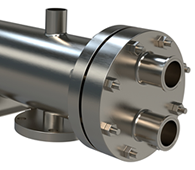

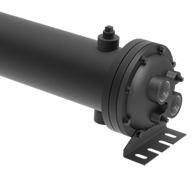

Clean In Place Heat Exchanger System

Heat exchangers are a crucial component in a number of industries. Their primary role is to transfer heat from one medium to another seamlessly. However, a vital aspect of maintaining their operation and longevity is regular cleaning, best achieved through a process known as cleaning-in-place or CIP. In essence, a clean-in-place heat exchanger is one that doesn't need to be dismantled for routine maintenance and cleaning, saving considerable time and resources.

Heat exchangers often operate with fluids that can cause internal build-up, causing fouling and reducing the unit's efficiency. Over time, they can develop layers of scale, dirt, and other deposits that can substantially hamper their performance or even result in complete breakdowns. This is where the benefits of the CIP process come into play.

How CIP Heat Exchangers Work

The CIP process involves circulating high-temperature cleaning solutions through the heat exchanger to dislodge and remove this debris. Because this process doesn't require the heat exchanger to be dismantled, it enables faster, trouble-free maintenance with minimal disruption. It ensures that these pieces of equipment continue to operate at their optimal level, in turn maintaining the consistency and quality of the output of the larger systems they form part of.

Moreover, the CIP process is adjustable. It can be fine-tuned to the precise needs of each unit, depending on the extent and type of cleaning required. This adaptability ensures that every clean-in-place heat exchanger retains its usability and continues to perform its duties for a longer span, making it a clever investment in the long run.

Another significant advantage of clean-in-place heat exchangers is the reduction in the amount of manual labor required. Traditional cleaning methods necessitate each unit to be painstakingly pulled apart, cleaned, and then reassembled - a time-consuming and costly process. With CIP, businesses can save time, labor, and money.

Common FAQs

A Clean in Place (CIP) heat exchanger allows the internal surfaces of the heat exchanger to be automatically cleaned without disassembly. In this process, cleaning solutions, like water, detergents, or sanitizers, are circulated through the heat exchanger to remove product residues, contaminants, and bacteria. CIP is used in the food, beverage, and pharmaceutical industries to maintain hygiene and safety standards, reduce downtime, and improve efficiency. The plate heat exchanger cleaning in place system ensures consistent and thorough cleaning, preventing contamination and maintaining product quality.

Clean in Place (CIP) is an automated cleaning system used to clean interior surfaces of equipment like pipes, vessels, and heat exchangers without disassembly. CIP ensures hygiene by removing residues, contaminants, and microorganisms using a series of cleaning agents like water, detergents, and sanitizers, which are circulated through the system.

How CIP Works:

- Preparation: The system is isolated from the production line and prepared for cleaning.

- Pre-Rinse: Water is circulated through the equipment to remove loose product residues.

- Cleaning Solution Circulation: A detergent or caustic solution is pumped through the system to dissolve fats, proteins, and other product residues.

- Intermediate Rinse: Water flushes out the cleaning solution.

- Sanitization: A disinfectant or sanitizer is circulated to eliminate any remaining bacteria or microorganisms.

- Final Rinse: Clean in Place system is rinsed using hot water to ensure no cleaning agents remain, making it safe for the next production cycle.

The two main types of CIP systems are single-use systems and recirculating systems:

- Single-Use CIP System: Fresh cleaning solutions (water, CIP 220 detergent, and sanitizer) are prepared for each cleaning cycle and then discarded after use. It is used for smaller systems or in processes where cross-contamination is a concern. It ensures hygiene by using new solutions for each cycle.

- Recirculating CIP System: In a recirculating system, the cleaning solution is reused in multiple cycles after being filtered and replenished. The cleaning agent is pumped through the system, collected, filtered, and then reused for the next cleaning cycle. This system is more cost-efficient and sustainable, especially in large-scale operations where minimizing water and detergent use is important.

CIP is essential to ensure the hygiene and safety of equipment used in production. CIP is needed for these reasons:

- Sanitation and Hygiene: CIP systems maintain cleanliness by removing product residues, bacteria, and other contaminants from internal equipment surfaces, ensuring food and beverages are safe for consumption.

- Prevention of Cross-Contamination: CIP prevents cross-contamination between product batches, especially in facilities processing different products or allergens. This ensures each batch meets safety and quality standards.

- Efficiency: CIP eliminates the need to disassemble equipment for cleaning, reducing downtime and labor costs. Automated cleaning processes allow facilities to maintain productivity without lengthy manual cleaning interruptions.

- Regulatory Compliance: CIP systems help manufacturers comply with strict health and safety regulations, like those set by the FDA or USDA, which mandate regular cleaning of equipment in food processing environments.

- Consistency and Reliability: Automated CIP systems ensure cleaning is thorough and repeatable, minimizing the risk of human error and ensuring consistent sanitation across production cycles.

The normal temperature for a CIP heat exchanger system depends on the cleaning phase and the nature of the residues being removed. The pre-rinse phase uses water at temperatures between 30-60°C (86-140°F) to remove loose product residues. For the caustic wash, an alkaline cleaning solution like sodium hydroxide is circulated at 70-80°C (158-176°F), ideal for breaking down fats, proteins, and organic materials.

The acid wash, which helps remove mineral deposits, is usually conducted at 60-70°C (140-158°F) using an acid detergent like phosphoric acid. The system is rinsed with water at around 20-40°C (68-104°F) to flush out remaining cleaning agents. These temperatures ensure thorough cleaning without damaging the equipment, while also preventing residue buildup.

A CIP valve is a component in CIP systems, designed to control and direct the flow of cleaning solutions, water, and other fluids through processing equipment like heat exchangers, tanks, and pipelines. These valves ensure the cleaning process is fully automated and efficient, allowing the controlled delivery of cleaning agents and rinse water to targeted areas without disassembly.

CIP valves are equipped with features to ensure sanitary operation, like stainless steel construction, easy cleaning, and minimal dead space to prevent contamination. Types of CIP valves include mix-proof valves, butterfly valves, and seat valves, which manage the separation of product flow and cleaning solutions, ensuring there is no cross-contamination between different phases of the cleaning process. By controlling fluid flow within the CIP system, valves contribute to maintaining hygiene, optimizing cleaning efficiency, and ensuring safety.