Heat Exchangers for Liquid Egg Processing

Heat Exchanger

These heat exchangers are specifically designed to handle the unique viscosity and thermal sensitivity of liquid eggs, ensuring efficient heat transfer without compromising the product's integrity.

The design of liquid egg heat exchangers typically features stainless steel tubes, which offer durability and ease of cleaning while adhering to stringent hygiene standards. Inside these tubes, the product is gently heated or cooled, with the tubular system allowing for uniform temperature distribution. The thermal process is precisely controlled to prevent overheating, which could lead to coagulation of the proteins and impact the egg's ability to emulsify, foam, or gel.

Equally important is the unit's capacity to handle rapid cooling after heating, which is critical to halt the pasteurization process at the exact moment and prevent overcooking. Advanced models can even facilitate regenerative heating, where the incoming cold product is pre-heated by outgoing warm product, enhancing energy efficiency. Heat exchangers are essential in meeting the demands of high-volume liquid egg processing, offering an effective means to manage the thermal treatment that safeguards both quality and safety.

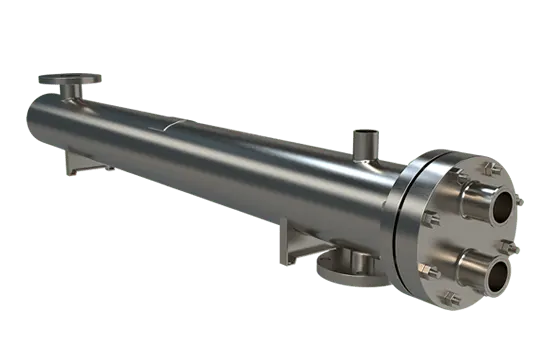

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

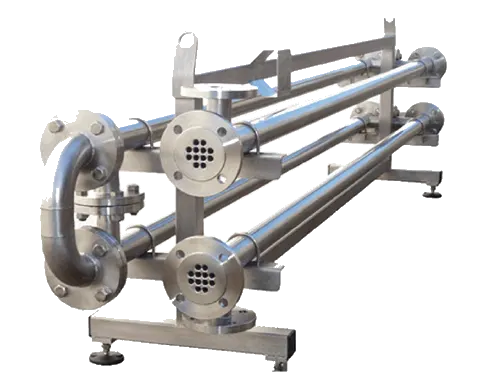

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing