Wort Cooling Heat Exchangers

Heat exchangers specifically designed for wort cooling employ materials such as stainless steel that not only provide durability but also enable superior thermal conductivity. These systems facilitate the swift removal of heat from the hot wort, ensuring it reaches the ideal lower temperatures required for fermentation without exposing the brew to potential microbial contamination.

The innovation in this sector has led to intricate designs where plates or tubes maximize the surface area in contact with the wort, thereby accelerating cooling while maintaining consistency in temperature throughout the batch. The heat taken from the wort is often repurposed, improving energy efficiency within the brewing facility and reducing the environmental footprint of the operation. Modern wort chillers are engineered to be easy to clean and maintain, further streamlining the brewing process. Their effective heat transfer capabilities are fine-tuned to meet the demands of an industry where precision and reliability are non-negotiable. With customization options available, breweries of all sizes can integrate these heat exchangers into their systems, ensuring that their unique brewing requirements are met, and beer quality is upheld.

Efficient and reliable, wort cooling heat exchangers remain indispensable in the commercial brewing equipment sector, reflecting an unwavering commitment to innovation, sustainability, and the art of brewing.

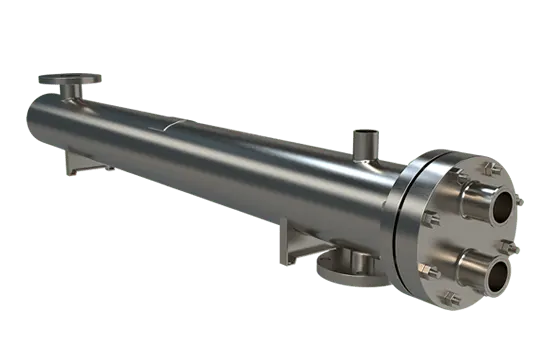

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

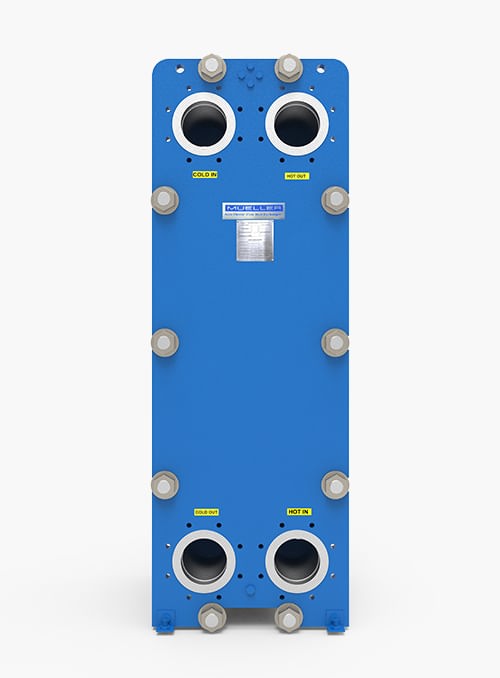

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

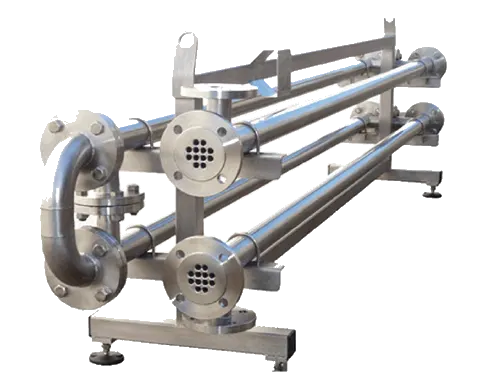

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing

More About Wort Cooling

Wort Cooling in the Beer Making Process

Chilling your wort is a crucial step in the beer-making process. Quickly lowering the temperature of your wort to the optimal pitching temperature and then adding your yeast culture is indispensable for brewing high-quality beer. In the following sections, I'll delve into why rapid wort cooling is so important.

The Importance of Quick Wort Cooling

One of the first concepts I introduce to students in my beginner brewing classes is the “danger zone,” which ranges from about 160°F down to pitching temperatures, roughly 75°F or lower. This range is critical because certain wild yeasts and bacteria can survive and thrive at these temperatures. Above 160°F, these organisms are inhibited. The faster you can chill your wort through this temperature range and pitch your yeast culture, the less chance these off-flavor-causing nuisances have to settle into your wort. Prompt cooling ensures that your yeast becomes the dominant culture in the wort, out-competing any unwanted wild organisms that may have entered the wort.

Wort Composition and Its Role in Beer Making

Wort is the sweet liquid extracted from the mashing process during brewing. It contains sugars, proteins, and other compounds that are essential for fermentation and ultimately define the character of the beer. The wort must be boiled to sterilize it and to extract flavors from the hops. After boiling, it’s crucial to cool the wort quickly to prepare it for fermentation.

Preventing Off-Flavors and Preserving Quality

Rapid chilling of the wort is vital to reduce or eliminate certain compounds that contribute to off-flavors. One notable compound is Dimethyl Sulfide (DMS), which imparts a creamed corn or cooked vegetable flavor or aroma. DMS is produced from a precursor, S-methyl-methionine (SMM), while the wort is hot. During the boil, DMS volatilizes and is removed from the beer. If the wort takes too long to cool, more DMS can stay in solution, potentially causing unwanted flavors and smells in the finished beer.

Achieving a Good Cold Break

Quick chilling also facilitates the precipitation and separation of proteins and solids (known as trub) from the wort. This process is called the “cold break.” A good cold break leads to clearer beer, prevents chill haze, and helps the beer last longer without degradation. Proteins that remain in suspension can cause haze and affect the beer's stability over time. By rapidly cooling the wort, these proteins coagulate and settle out, improving the overall quality and clarity of the beer.

Preserving Hop Aromas

Lastly, rapid wort cooling helps preserve the aromatic qualities of the hops. Aroma hops added near the end of the boil are more susceptible to volatilization if the wort is not chilled quickly. By quickly lowering the temperature, these aromatic compounds are retained, enhancing the hop character in the finished beer.