CBD Extraction and Oil Filtration Machine

Sanitary Heat Exchangers for CBD

The extraction of cannabis oil is a meticulous process that demands precision and control, especially in thermal management. In the CBD extraction industry, heat exchangers' primary function is to regulate processing temperatures with high accuracy, preserving cannabinoids, terpenes, and other delicate compounds in the product. Sanitary-grade shell and tube heat exchangers are widely used due to their efficiency and reliability.

These units are custom-designed to meet the specific needs of cannabis oil production, enabling precise cooling and heating during extraction and post-extraction processes. This setup provides optimal control of the extract’s temperatures, effectively preventing thermal degradation and ensuring consistent quality in the final product.

The robust construction of shell and tube exchangers ensures they withstand the rigorous demands of continuous operation and meet the stringent sanitation standards required for product safety. The versatility of these heat exchangers allows for customization of materials, sizes, and configurations to suit various extraction methodologies. Consequently, they are an indispensable component in the CBD extraction industry, where effective heat transfer is key to producing a high-quality product.

CBD extraction involves several critical steps using advanced equipment to ensure high-quality product yield and efficiency:

CBD extraction involves several critical steps using advanced equipment to ensure high-quality product yield and efficiency:

- Preparation: Raw cannabis material is prepared by grinding or milling to increase surface area for extraction.

- Extraction: CBD is extracted using solvents like ethanol or hydrocarbons in specialized extraction vessels.

- Cryogenic Cooling: Solvents are chilled to subzero temperatures using heat exchangers (e.g., plate or tubular) to maximize extraction efficiency.

- Evaporation: After extraction, solvents are evaporated in heat exchangers, separating CBD oils from the solvent.

- Condensation: Vapors from the evaporation process are condensed back into liquid form for solvent recovery and reuse.

- Filtration: CBD oil undergoes filtration to remove plant waxes and impurities, enhancing purity.

- Distillation: Further purification through distillation separates CBD from other cannabinoids and compounds.

- Winterization: CBD oil is mixed with ethanol and frozen to remove fats and lipids.

- Decarboxylation: Heating converts cannabinoid acids (e.g., CBDA) into active cannabinoids (e.g., CBD).

- Testing: Final CBD extract is tested for potency, purity, and contaminants before packaging.

Each stage requires precise temperature control and specialized equipment like heat exchangers to optimize extraction efficiency and product quality in the CBD extraction process.

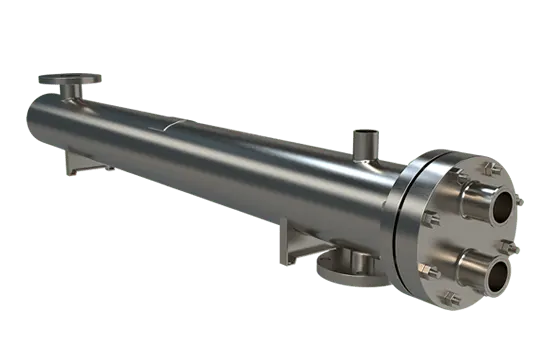

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

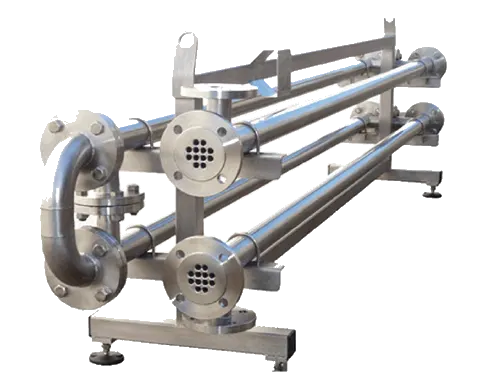

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing