Sanitary Heat Exchangers

Sanitary heat transfer applications in the pharmaceutical and beverage industries are crucial for maintaining product integrity and safety. Utilizing advanced stainless steel heat exchangers, these applications ensure precise temperature control during processing, essential for product quality. From sterilization to cooling, these systems provide efficient heat transfer while adhering to strict sanitary standards, making them indispensable in creating safe, reliable products.

- Temperature Control: Sanitary heat exchangers are crucial in pharmaceutical manufacturing, ensuring precise temperature control for the safety and efficacy of drugs.

- Pasteurization: In the dairy industry, they play a key role in pasteurization processes, maintaining the quality and longevity of milk products.

- Cooling & Heating: Utilized in the beverage industry, sanitary heat exchangers contribute to the cooling and heating processes, preserving flavor integrity.

- Bioreactors: They are essential in the biotech sector for regulating temperatures in bioreactors, directly impacting product yield and quality.

- Wort Cooling: In craft brewing, sanitary heat exchangers are vital for wort cooling and fermentation processes, impacting flavor development and stability.

- Extraction: Sanitary heat exchangers are used in the cannabis industry for precise temperature control in extraction processes, maximizing purity and potency.

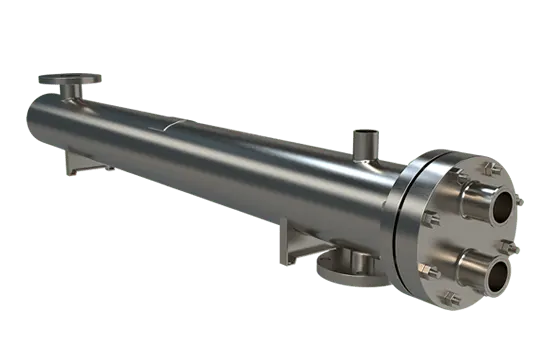

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Bio-Tech

Plate & Frame:

Sanitary Applications

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

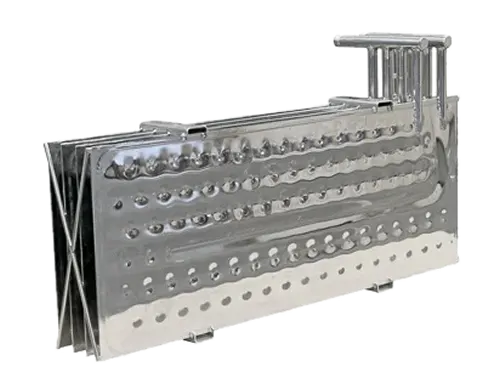

Embossed Plate:

Sanitary Applications

- Tanks

- Conveyor Lines

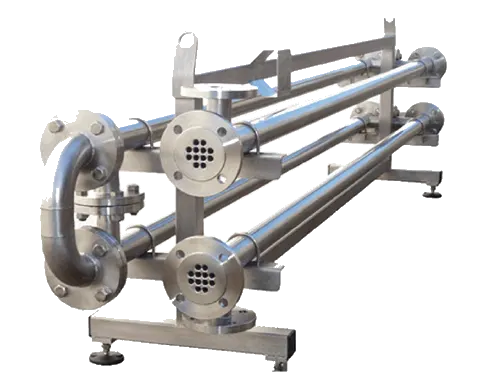

Tube-in-Tube:

Sanitary Applications

- High Viscosity

- High Temperature & Pressure

- Temperature Crossing