Reverse Osmosis Heat Exchangers

In many reverse osmosis systems, heat exchangers designed to support the heating or cooling of fluids involved in sanitary water processing. Heat exchangers tailored for RO water are meticulously engineered to meet the needs of sanitary applications, ensuring quality control, streamlining maintenance, and optimizing thermal transfer.

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing

Portable Reverse Osmosis Water To Water Heat Exchangers

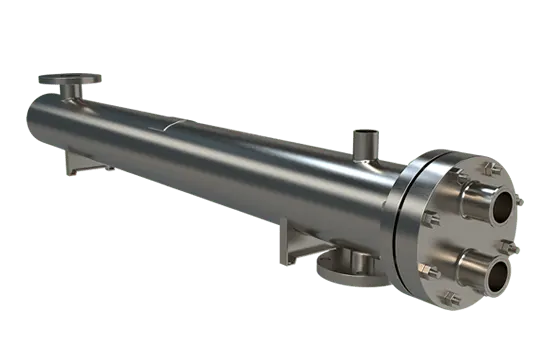

Shell and Tube RO Water Exchangers

Shell and tube heat exchangers, a common type used in RO operations, offer designs that enable complete drainage and prevent cross contamination—a crucial aspect in sanitary applications. An array of models are available, catering to a variety of sanitary needs—from multi-pass units, to sanitary 3A certification, to bellowed U-tube designs that allow for differential thermal expansion without stress. These exchangers are constructed from materials such as 304L and 316L stainless steel, duplex steels, and a range of corrosion-resistant alloys, these heat exchangers can withstand the rigors of commercial applications.

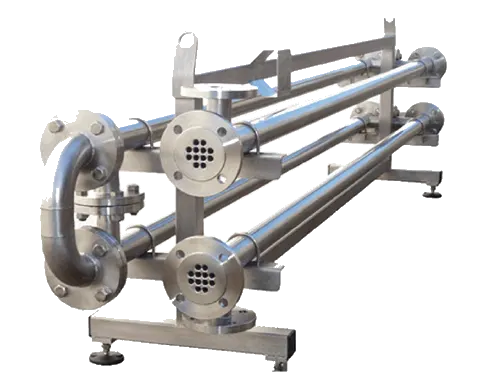

Tube-in-Tube RO Water Exchangers

Likewise, tube-in-tube heat exchangers present a solution when dealing with more viscous fluids, like those laden with fibers, particles, or with a thicker constitution. The use of concentric tubes- sometimes with corrugated surfaces- amplifies the rate of heat transfer while optimizing space. In scenarios where aggressive fluids are involved, more robust materials such as duplex stainless steel are used to help extend longevity.

Brazed Plate

Brazed plate heat exchangers, recognized for their compactness and maintenance-free performance, also achieve highly efficient temperature modulation for RO water. They stand as cost-effective options for RO water applications, facilitating tight approach temperatures between the utility and process fluids.

Gasketed Plate & Frame

Lastly, plate and frame exchangers represent a popular choice in this arena, bringing robust construction suited for the high purity requirements of RO water heat transfer. Such exchangers utilize gaskets that vary in composition to suit the unique demands of different industrial processes. Gasketed plate exchangers offer easy servicing and gasket or plate replacement, unlike other types of units.

Heat exchangers specifically designed for RO water are instrumental in various processes across industries involving pharmaceuticals, biotechnology, and more. Their critical role in heating, cooling, steam generation, and other temperature-sensitive procedures underlines their significance to sanitary and industrial operators in maintaining process efficiency and operational longevity.