Milk Pasteurization Heat Exchangers

Pasteurization heat exchangers find applications in a wide range of industries, extending beyond dairy and beverages to include beer brewing, pharmaceuticals, and even cosmetics, ensuring product safety and extending shelf life.

- Shell & Tube: Shell and tube heat exchangers, used in pasteurization, feature robust designs suitable for high-temperature applications across numerous industry sectors.

- Plate & Frame: Plate and frame heat exchangers, efficient in pasteurization, offer high heat transfer efficiency with their stacked plate design, ideal for various fluids.

- Clean-in-Place (CIP): CIP systems in pasteurization allow for efficient, automated cleaning without disassembly, ensuring heat exchangers maintain optimal hygiene and performance standards.

- Milk & Dairy: Pasteurization in milk and dairy industries is essential for ensuring safety, extending product shelf life, and preserving nutritional value efficiently.

- Viscous Foods: For viscous foods like jams, jellies, baby food, and soups, heat exchangers ensure uniform heating, preserving texture and nutritional quality.

- Canned Goods: Heat exchanger pasteurization for canned goods ensures safety and quality, extending shelf life while maintaining flavor and nutritional content effectively.

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Bio-Tech

Plate & Frame:

Sanitary Applications

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

Milk Pasteurization Heat Exchangers

Heat Exchanger

These sanitary devices are designed to efficiently transfer heat between the pasteurizing hot water or steam and the milk, without direct contact. Utilizing stainless steel plates or tubes, they create a partition that allows the heat to pass while maintaining the integrity and separation of the fluids.

The functionality of such heat exchangers lies in their ability to raise the milk's temperature to the required pasteurization point swiftly, usually around 161°F for at least 15 seconds, and then cool it down rapidly to halt microbial growth. The design of these heat exchangers is optimized to maximize surface area, facilitating quick and even heat transfer, a crucial factor for both energy efficiency and product quality. Advanced models also incorporate features to recover heat from the pasteurized milk, using it to preheat incoming batches, further conserving energy.

Behind the scenes, the effectiveness of heat exchange devices in milk pasteurization hinges on the precise control of temperatures and flow rates. Ensuring that each molecule of milk reaches the requisite pasteurization temperature without overheating is imperative to maintain product quality. This balance of efficiency and precision underpins the process, allowing for high-volume production while upholding strict hygiene standards, extending shelf life, and providing safe consumption for dairy products worldwide.

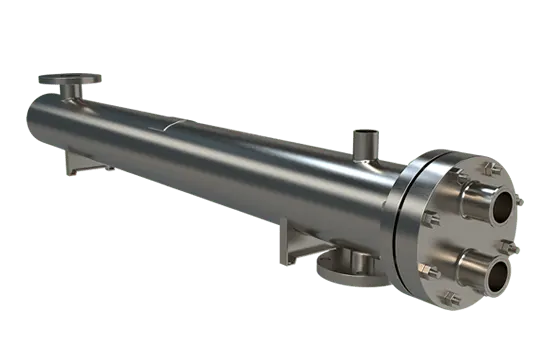

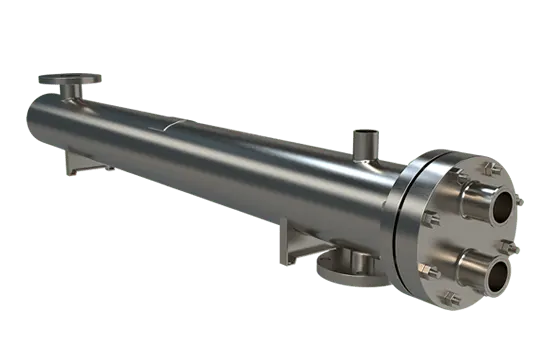

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

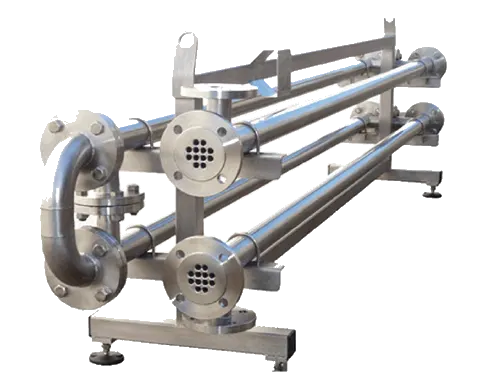

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing

Pasteurization Heat Exchangeres

In the dairy industry, the safety and quality of milk and related products hinge heavily on effective pasteurization processes. Pasteurization, designed to sterilize milk by heating it to a specified temperature to eradicate pathogenic microorganisms while preserving its nutritional properties, relies fundamentally on the efficacy of heat exchangers. These specialized devices are indispensable for the precise and efficient heat transfer required in pasteurization.

Plate Heat Exchangers

Among the most extensively utilized heat exchangers in dairy operations are plate heat exchangers. The arrangement of the plates allows for optimal heat transfer efficiency due to the expansive surface area. The design ensures effective thermal conduction, crucial for maintaining the stringent thermal profiles necessary for pasteurization. See more about Plate and Frame Heat Exchangers.

.

Tubular Heat Exchangers

Tubular heat exchangers, or shell-and-tube heat exchangers, are characterized by a bundle of tubes enclosed within a cylindrical shell. Their configuration is preferable for viscous fluids or those containing particulates, aligning with the requirements for processing certain dairy products. These exchangers leverage the large surface area of the tubes to achieve substantial heat transfer, suited for more complex fluid dynamics in pasteurization processes.

Scraped-Surface Heat Exchangers

Designed to handle high-viscosity products prone to fouling, scraped-surface heat exchangers integrate a rotating blade mechanism that continuously removes any buildup on the heat exchange surface. This ensures consistent thermal conductivity and prevents the degradation of heat transfer efficiency. Such exchangers are pivotal for achieving the continuous and uniform heating and cooling vital in high-viscosity or sensitive dairy product pasteurization.

Mechanism of Heat Exchangers in Pasteurization

During pasteurization, milk is typically subjected to a temperature of approximately 72°C (161°F) for a duration of 15 seconds, following the High-Temperature Short Time (HTST) pasteurization protocol. Heat exchangers execute this process by swiftly heating the milk to the target temperature and then cooling it abruptly to arrest any undesirable thermal effects on flavor or nutritional integrity.

The milk progresses through the heated section of the heat exchanger, absorbing thermal energy from a hot medium, generally water or steam. Subsequently, it transitions to the cooling phase, where it discharges heat to a colder medium, reducing its temperature to safe storage levels expeditiously. This rapid thermal cycling is fundamental to effective pasteurization while preserving the product’s quality.

Advantages of Heat Exchangers in Pasteurization

Thermal Precision and Product Consistency

Heat exchangers offer meticulous temperature regulation and consistent heat distribution, ensuring uniform pasteurization across all batches. This precision is critical for maintaining the taste and quality of dairy products, a non-negotiable aspect for both consumer satisfaction and brand integrity.

Sanitary Construction

Modern heat exchangers are engineered for superior hygiene, constructed from materials that facilitate easy cleaning and maintenance, thereby minimizing contamination risks. This hygienic design is essential in the dairy sector, where adherence to rigorous sanitary standards is imperative.

Operational Versatility

The application versatility of heat exchangers spans a range of dairy products, including milk, cream, yogurt, and cheese. Selecting the appropriate type of heat exchanger for specific product requirements ensures optimal thermal performance and quality assurance throughout the pasteurization process.