Enhancing Wine Must Processing with Heat Exchangers

By utilizing a network of tubes or plates which facilitate the transfer of heat between two fluids, they maintain the must at desired temperatures without direct contact between the hot and cold fluids. This process not only preserves the organoleptic qualities of the wine but also ensures that fermentation proceeds under optimal conditions, which is crucial for developing the desired flavor profile and preventing unwanted microbial activities.

In the context of winemaking, heat exchangers are an effective solution to control the exothermic nature of fermentation where precise cooling is often necessary to prevent overheating. The industrial-grade construction of these exchangers, featuring materials like stainless steel, withstands the acidic nature of wine must while providing reliable and efficient heat exchange. Furthermore, the design of Wine Must heat exchangers allows for easy cleaning and maintenance, which is paramount in the wine industry to meet stringent hygiene standards.

These systems can come in various configurations, such as shell and tube, or plate and frame, offering a range of heat transfer efficiencies to meet the specific needs of a winemaking operation. With their robustness and efficiency, Wine Must heat exchangers represent a vital investment for wineries aiming to control fermentation temperatures and enhance the quality of their product.

Must (from the Latin vinum mustum; meaning 'young wine') is the freshly crushed fruit juice, usually grape juice, containing the skins, seeds, and stems of the fruit. The solid portion, known as pomace, makes up 7–23% of the total weight of the must. This initial stage of winemaking is crucial, and the role of heat exchangers in managing the temperature of the must can greatly impact the quality of the final product.

Optimizing Temperature Control

Maintaining the optimal temperature of wine must is vital for proper fermentation. Heat exchangers are essential in this process, allowing winemakers to precisely control the temperature, whether cooling or heating the must. This precision helps in preventing spoilage and ensures that fermentation occurs under the best possible conditions, which is crucial for the final character of the wine.

Efficiency in Juice Extraction

The length of time the pomace stays in the juice affects the wine's flavor and character. When the desired time is reached, the juice is drained, and the pomace is pressed to extract the remaining juice. Using heat exchangers during this stage helps in maintaining the right temperature, making the extraction process more efficient and preserving the quality of the juice.

Versatility in Winemaking

Heat exchangers also play a role in creating Süssreserve, a sweetening component added before bottling. Additionally, some winemakers use the pomace to produce a second batch of wine by adding water, letting it sit, and then draining the liquid. This second batch can serve as a drink for winery employees or as a base for pomace brandies. Heat exchangers ensure that the temperature remains controlled throughout these processes, enhancing both efficiency and quality.

Applications Beyond Wine

Must is not only used in winemaking but also in the production of traditional balsamic vinegar. The high glucose content, typically between 10 and 15%, makes it a valuable ingredient in various cuisines as a sweetener. Unlike commercially sold grape juice, which is filtered and pasteurized, must is thick, opaque, and comes in various shades of brown and purple.

Traditional Balsamic Vinegar Production

In the Emilia-Romagna region of Italy, must is essential for making traditional balsamic vinegar. The acetification and maturation processes, involving selected bacterial colonies and aging in precious barrels, require precise temperature control, which heat exchangers can provide. After a minimum maturation period of 60 days, expert technicians test the vinegar for quality.

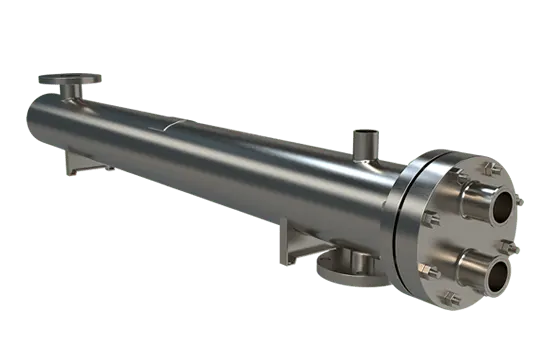

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

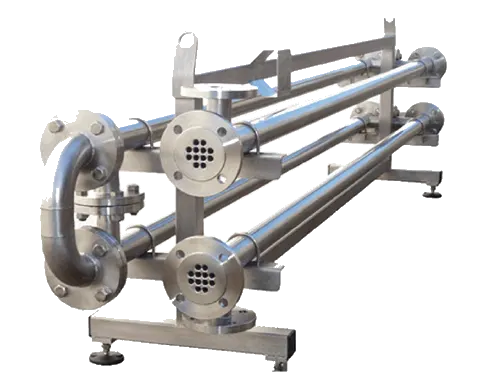

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing