Our Sanitary Heat Exchangers

Through our indirect exchangers, heat from the vapor is transferred to the coolant, causing the vapor to lose energy and condense into a liquid state. Owing to their role in energy recovery and waste heat utilization, sanitary vapor condensers are instrumental in enhancing system efficiency and reducing operational costs. Manufacturers of these condensers prioritize robust construction and use materials such as high-grade stainless steel, which not only withstands the rigorous conditions of industrial processes but also maintains the purity of sensitive products.

Performance optimization involves precisely calculating the heat transfer area and selecting appropriate materials and design parameters to harmonize with the specific thermal duties required by the application. By incorporating features like cleanable surfaces and ease of maintenance into their design, these condensers ensure reliability and longevity, thereby providing value to facilities that prioritize both performance and sanitation in their thermal exchange processes.

During industrial processes including distillation and chemical manufacturing, as well as in the food, dairy, pharmaceutical, and chemical industries, sanitary vapor condensers cool and condense vapor into liquid form. As the vapor passes through the condenser, it comes into contact with cold surfaces or tubes causing its temperature to drop, changing it back into a liquid. Vapor condensers are essential for the recovery, recycling, or disposal of vaporized materials because they condense the vapor into a liquid. By collecting and recycling vaporized materials, vapor condensers lower pollutants and reduce emissions by capturing and reusing vaporized substances.

Each type of condenser manages vapor, improves productivity, and maintains purity in sensitive processes across the pharmaceutical, chemical, food, and research fields. Some of the available types of vapor condensers include:

- Pharmaceutical Units: These condensers are designed specifically for pharmaceutical applications, where accuracy and purity are especially important. To adhere to stringent sanitary regulations and prevent contamination, they’re made with stainless steel or glass-lined surfaces. Pharmaceutical condensers enable procedures like distillation and active component purification by including features to ensure proper vapor recovery and temperature control, while supporting the distillation and purification of active ingredients.

- Knock-Back Condensers: To minimize emissions and prevent the loss of valuable materials, knock-back condensers condense and return vaporized solvents to their original container or system. They’re useful in closed-loop systems where solvents must be condensed after vaporization so they can be reused. In small-scale production and laboratory environments, knock-back condensers improve performance.

- Cold Trap Condensers: Cold trap condensers work at low temperatures to capture and condense reactive or high-boiling-point vapors that are incompatible with conventional condensers. In pharmaceutical and research labs, they’re used in vacuum systems, and for freeze-drying, and the preservation of volatile chemicals. By absorbing moisture, cold traps can protect vacuum pumps and prevent contamination, organic solvents, and other condensable gases.

- Reflux Condensers: In distillation systems, reflux condensers maintain the system's balance by condensing vapor that rises down a column and allow it to flow back down. Reflux condensers improve the purity of distillation operations by returning condensed liquid to the boiling mixture. This makes reflux condensers ideal for product refinement in chemical and pharmaceutical applications.

- Solvent Recovery Condensers: The liquid solvent can be recovered and used again thanks to solvent recovery condensers, which collect and condense the vapors from solvent-based processes. Because it increases sustainability, lowers costs, and reduces emissions of volatile organic compounds, it's important for industries dependent on solvents for extraction and purification.

Vapor condensing is the process of transforming vapor back into a liquid state by cooling it to its dew point. In this process, vaporized substances lose heat as they come into contact with a cooler surface or medium, like a condenser. This cooling causes vapor molecules to slow down and coalesce, forming liquid droplets.

Vapor condensing is widely used in industrial applications, including distillation, refrigeration, and chemical production. It enables the recovery and reuse of volatile compounds. In the pharmaceutical and food industries, vapor condensing is essential for hygienic processes requiring precise temperature control, purity, and containment of volatile substances. Vapor condensing also meets standard regulatory requirements.

A substance's gaseous state is called vapor, and the liquid that results from the condensation of vapor is called condensate. When a liquid or solid is heated until it turns into a gas, vapor is created. The first phase of substance in processes like boiling or evaporation is called vapor. When vapor cools and reaches its dew point, it transforms back into a liquid, known as condensate. Vapor molecules slow down, lose heat, and change into droplets to form condensate during the condensation process.

A gas that can return to its liquid state by cooling or applying more pressure is known as a condensable vapor. A condensable vapor starts to condense and form liquid droplets when it reaches its dew point, which is the temperature at which it can no longer exist as a gas. Condensable vapors include chemicals like alcohol or certain hydrocarbons, as well as steam, which condenses into water. Industrial operations like distillation, refrigeration, and chemical synthesis include condensable vapors, where managing the phase transition between vapor and liquid is important for recovering and purifying substances.

Because of their stability at high temperatures, chemical resistance, and longevity, high heat polymers are essential for vapor condenser operations. In industrial settings, they preserve purity and prolong the life of condensers by withstanding heat variations, reducing the risk of bacteria. These polymers preserve system integrity and product purity. Because they endure harsh sanitization procedures and temperature extremes without sacrificing performance, they extend the life of equipment and lower maintenance costs.

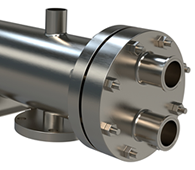

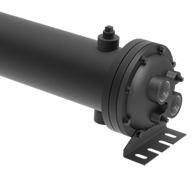

HeatX offers high-quality vapor condensers in both stock and custom units, available in various sizes and materials to meet customer needs. Known for superior durability and performance, our condensers are TEMA, ASME, 3-A, PED, and CRN certified, to meet industry standards. Sanitary Exchangers’ precision and quality provide customers with maximum performance and value. Options include 1-pass, multi-pass, U-tube, straight tube, and brazed plate units. Pharmaceutical, knock-back, cold trap condensers, reflux, and solvent recovery units are available. Our Sanitary 3A Condensers are USDA and FDA-approved, making them ideal for applications requiring strict hygiene standards.