Sterile Water Heat Exchangers

Typical processes that benefit from such sophisticated heat exchangers include the production of API or formulated pharmaceuticals, handling of blood, plasma, or growth media, and the generation and condensing of pure steam. They are also instrumental in bio-kill processes, waste neutralization, and point-of-use cooling or heating applications.

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing

Heat Exchangers for Sterile Water

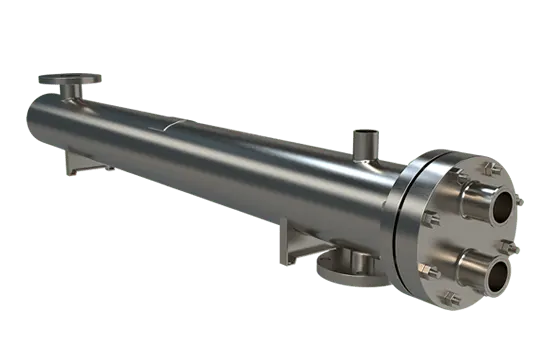

Shell and Tube Sterile Water Exchangers

With shell diameters ranging from 2" to 36" and lengths from 12” to 65’, these heat exchangers are engineered for a high degree of thermal efficiency and reliability. Available in multiple configurations, including multi-pass, U-tube, straight tube, and double tube sheet units, they cater to specific process requirements while maintaining impeccable cleanliness standards.

The hallmark shell and tube heat exchangers lies in their sanitary finish—an imperative feature for processes where cleaning is frequent and vital. The design ensures a 100% drainable system, with double tube sheets to prevent cross-contamination. Furthermore, the provision of sanitary process-sided connections and optional electro-polishing reflects our commitment to enhancing sanitary performance and extending the longevity of the heat exchangers in the face of wear and corrosion.

Materials for Sterile Water Heat Transfer

Durability and resistance to corrosion form the backbone of these systems, with construction materials such as 304L, 316L, and duplex stainless steels including 2205 and 2507. For more demanding environments, Southwest Thermal provides options crafted from alloys renowned for their robustness against corrosion, such as Hastelloy, Alloy 20, Monel 600, AL-6XN, Titanium, and copper-nickel alloys.

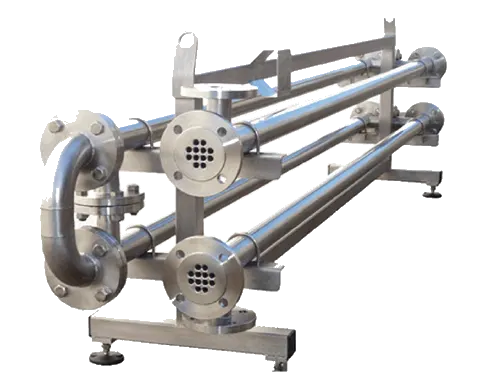

Tube-in-Tube for Sterile Water

For applications dealing with high fiber content or significant suspended particles, the tube-in-tube heat exchanger presents an innovative solution. Its dual concentric corrugated tubes enhance the heat transfer rate while allowing for a compact design. The product-contact components are made from 316L stainless steel, with an option for duplex stainless steel when facing aggressive fluids. Non-contact areas are built using 304 stainless steel to maintain structural integrity.

To answer the call for compact, low-maintenance solutions, consider a brazed plate heat exchanger. Constructed from stainless steel and other alloys, these units excel in sterile water applications by facilitating very close approach temperatures, ensuring economical operational costs and high performance.

Gasketed Plate & Frame

In addition, plate and frame exchangers are available to satisfy the stringent heat transfer demands of sterile water. Offering a construction primarily in 304 or 316 stainless steel, these exchangers provide flexibility with gaskets available in a variety of materials including Nitrile (NBR), Silicone, EPDM, Viton, or Butyl, tailored to specific design conditions.