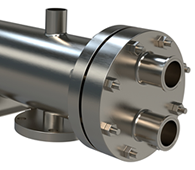

Sanitary Evaporator Heat Exchanger

Sanitary condensers serve important applications in a number of industries. We offer both stock and custom units in a vaariety of sizes and materials, depending on the customer's requirements. Call today to speak with our knowledgeable staff.

- Certified: Available TEMA, ASME, 3-A, PED and CRN certifications.

- Available Options Sight glasses, level gauge ports, CIP spray ball assemblies, and electro-polished tube surfaces avaiable, among others.

- High Quality: Constructed of 304L, 316L, or alternative alloys for superior durability and performance.

- Efficiency: Superiority in design and build quality allow us to offer our customer the best possible efficiency and value.

- Configurations: Available in 1-pass, multi-pass, U-tube, and straight tube configurations.

- Types: Pharmaceutical units, knock-back and cold trap condensers, reflux, and solvent recovery are just a few types that are available.

Sanitary 3A:

Food, Beverage and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

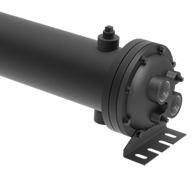

Non-Sanitary:

Non Food Related

- Non Food Applications

- Carbon Steel or Stainless

Our Sanitary Evaporators

Primarily used in the food, beverage, and pharmaceutical sectors, these evaporators are designed to meet strict hygiene and sanitation standards while efficiently transferring heat.

The construction of sanitary evaporators often involves high-grade materials, such as stainless steel, that can withstand rigorous cleaning protocols and resist corrosion. Heat transfer in sanitary evaporators is facilitated through the use of either tubular or plate heat exchangers, depending on the specific requirements of the application at hand.

The heat exchanger technology in sanitary evaporators enables the precise control of temperature, ensuring that the quality of sensitive products is preserved during processing. For instance, in the dairy industry, these evaporators concentrate milk by removing water content under carefully controlled temperatures to avoid damaging proteins and other important nutrients. Similarly, in pharmaceutical manufacturing, maintaining product integrity during processes like solvent recovery is essential, and sanitary evaporators perform this task with high efficiency and reliability.

Attention to design detail is paramount, emphasizing easy accessibility and cleanability to prevent any contamination risks. Additionally, the energy efficiency of sanitary evaporators is of considerable importance to industrial users, designed to optimize heat transfer rates, minimize thermal losses, and reduce overall operational costs. This focus on combining hygienic design with thermal effectiveness makes sanitary evaporators an indispensable component in industries where product purity and quality are non-negotiable.