Cannabis Industry Heat Exchanger

Sanitary Heat Exchangers for Cannabis

In the cannabis industry, heat exchangers, particularly shell and tube models, have become essential components in cannabis extraction systems. These devices optimize heat transfer, ensuring efficient extraction while preserving the delicate compounds of the cannabis plant.

Sanitary shell and tube heat exchangers are designed to rapidly heat or cool extraction media, like CBD Oil, to precise temperatures. In this setup, the process fluid flows through inner tubes while the utility fluid circulates in the outer shell, indirectly heating or cooling the process fluid through the tube walls. These exchangers can handle the significant temperature changes required in extraction methods such as supercritical CO2 or ethanol extraction. Their ability to quickly transfer heat, deal with phase changes during extraction and post-processing stages, maintain the purity and potency of cannabinoids throughout the extraction processand, and to winterize or process cannabis distillates make them essential to the industry.

Heat exchangers play a critical role in extraction, winterization, solvent recovery, decarboxylation, and distillation of cannabis products. Manufacturers construct these heat exchangers with materials that meet industry standards for purity and safety, including designs meeting 3-A Sanitary Standards. Advanced design and engineering have also addressed scalability and maintenance concerns, affording seamless integration into existing extraction systems.

Botanical Extraction Solutions

Achieving high-purity CBD and THC products demands advanced knowledge of botanical extraction processes to maximize yield and productivity. HeatX leads the CBD/THC extraction sector with a comprehensive range of plate and tubular heat exchangers tailored for your extraction needs.

Ethanol Extraction:

Cryogenic Cooling: Ethanol undergoes subzero chilling using plate or tubular heat exchangers, utilizing specialized heat transfer fluids like Dynalene, to enhance extraction performance.

Evaporation: Extracted CBD/THC oils are separated from ethanol solvent in heat exchangers, followed by evaporation into a flash tank to reclaim ethanol vapors and isolate CBD/THC oils.

Condensation: Ethanol vapors are condensed back into liquid form for recycling using advanced plate or tubular heat exchangers.

Energy Recovery: Heat exchangers recover energy between evaporation and cryogenic cooling stages, reducing chiller workload and optimizing process flow.

Hydrocarbon Extraction:

Cryogenic Cooling: Propane or Butane hydrocarbons are chilled to liquid form in plate or tubular heat exchangers before being used as solvents for CBD and/or THC extraction.

Evaporation and Recovery: Hydrocarbons evaporate at ambient conditions, allowing for efficient recovery while CBD/THC oils are collected.

Condensation: Gaseous hydrocarbons are condensed back into liquid form for reuse in subsequent extraction cycles using heat exchangers.

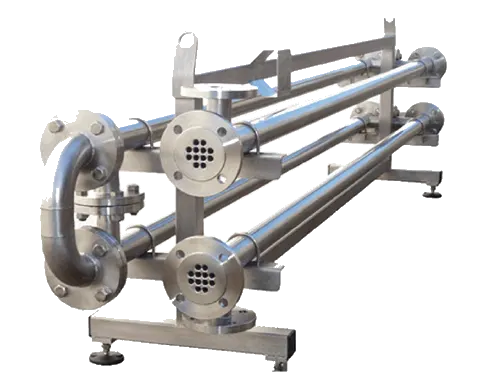

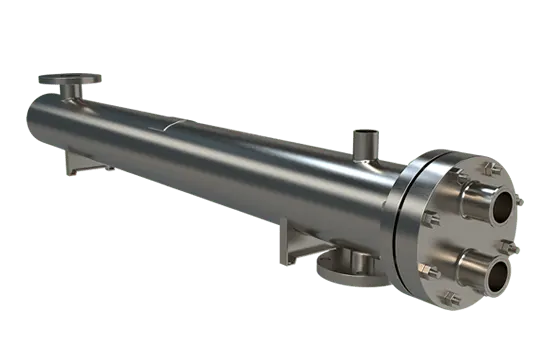

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models Available

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing