Food Products Heat Exchangers

Specifically designed for food and beverage processing, our high quality heat exchangers employ a variety of technologies and materials to deliver safe and effective transfer of energy between your utility and process fluids. One of the key applications includes pasteurization, where the exchanger heats food to eliminate pathogens, then quickly cools it to halt the process and maintain quality and safety.

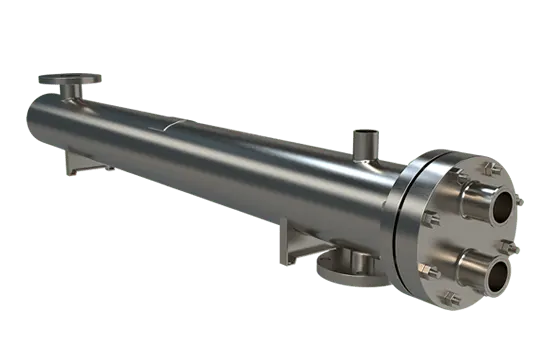

- Shell & Tube: Our food grade shell and tube heat exchangers ensure optimal thermal performance, sanitation, and durability, tailored for rigorous food industry standards.

- Plate & Frame: Plate and frame heat exchangers provide excellent thermal efficiency, easy maintenance, and hygiene, ideal for food processing applications requiring precise temperature control.

- Clean in Place (CIP): CIP clean-in-place heat exchangers streamline food processing by allowing efficient, automated cleaning without disassembly, ensuring hygiene and reducing downtime.

- Milk & Dairy: Milk and pasteurization heat exchangers maintain product safety by controlling temperatures, ensuring pathogen elimination, and preserving nutritional quality.

- Viscous Foods: Thick food products can often present design challanges, but our complete line of products provide solutions for almost any fluid.

- Alcohol: Our alcohol, brewing, and distillation heat exchangers range in size, material, and customization options to fit any application.

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Units Available

Plate & Frame:

Sanitary Applications

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

Sanitary Heat Exchanger for Food Industry

Another application is the chilling of products post-cooking to meet safety standards by rapidly reducing temperatures to limit bacterial growth. In confectionery manufacturing, heat exchangers are utilized to carefully temper ingredients like chocolate, ensuring the product solidifies with the desired crystalline structure and properties. Brewing and dairy industries also rely on these systems for efficient thermoregulation during fermentation and milk processing to maintain desired consistency and prolong shelf life.

Food Grade Materials

Food heat exchangers must adhere to stringent hygiene regulations, which dictate the regularity and thoroughness of cleaning cycles. Their design often features stainless steel components for corrosion resistance and ease of sanitation. The customization of heat exchangers to fit specific processing requirements ensures operational efficiency and energy conservation, contributing significantly to the optimization of food production processes. This specificity facilitates the industrial sector's ability to meet both consumer demands and regulatory requirements, highlighting the importance of these systems in maintaining the balance between productivity and product integrity.

Heat Exchangers in the Food Industry

Heat exchangers play diverse roles in the food industry, from refining cooking oil to maintaining appropriate temperatures for pasteurization, or heating soups and sauces. Adhering to strict health and safety standards in food production, heat exchanger design and manufacturing quality are paramount. For instance, milk requires heating for pasteurization, then rapid cooling to prevent spoilage. Similarly, other liquids like cooling oil and condiments need specific temperature processing to maintain taste and purity. Moreover, heat exchangers enhance energy conservation. As in milk pasteurization, the heat exchanger enables warm and cold milk to interact within the assembly without any mixture.

Custom-Tailored Solutions

Although the food industry demands high safety and quality standards, there's a scarcity of dedicated food-grade heat exchangers. Most used are not specifically designed for the sector, which may have economical benefits initially but potential challenges later. These industrial heat exchangers could previously be used for hazardous substances, lacking appropriate cleanliness for the food industry. Implementing these in food production might lead to contamination, spoilage, interrupted production, and costly replacements.

Food-grade exchangers can integrate effortlessly with existing systems, regulate temperature precisely without disrupting operations, and modify as per different food requirements. These sanitary devices adhere to strict safety and cleanliness standards, making them ideal for an industry increasingly scrutinized by consumers for safety. In a competitive industry with slim margins, food-grade exchangers help eliminate cross-contamination risk and focus on production expansion.