Sanitary & Hygienic Heat Exchangers

Standard and Custom Heat Transfer Equipment

Sanitary heat transfer applications require precision-engineered heat exchangers to maintain the integrity of the product. These systems ensure efficient temperature regulation for sensitive materials, adhering to rigorous health and safety standards. We are committed to partnering with you to create the most effective, cost-efficient, and practical solutions for your heat exchange needs.

- Evaporators: Utilize heat exchangers to concentrate solutions by removing water, essential in pharmaceutical ingredient preparation.

- Condensers: Capture and condense steam or vapors, playing a critical role in solvent recovery and distillation processes.

- Clean-in-Place (CIP): Heat exchangers support sanitization protocols, ensuring high-purity conditions for sensitive pharmaceutical production.

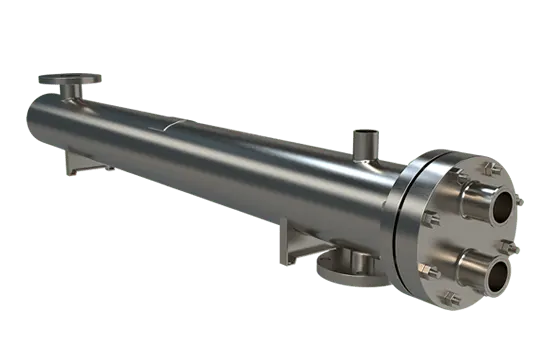

- Shell & Tube: Our shell & tube exchangers are built to exacting standards using the highest quality stainless steel and higher alloys. Built to 3-A standards upon request.

- Plate & Frame: We provide top-of-the-line sanitary plate and frame units boasting close approach temperatures, reduced fouling, easy cleaning, and optimized performance.

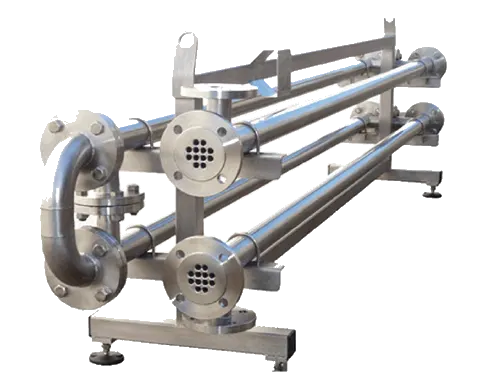

- Tube-In-Tube: Our line of sanitary tube-in-tube exchangers can be custom-built to spec using any range of sanitary fitting and materials.

Shell & Tube:

High durability and suitable for various sanitary applications

- Bio-Tech

- Clean-in-Place

- Evaporators & Condensors

Plate & Frame:

Highest BTU per Sq/Ft performance in heat transfer

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

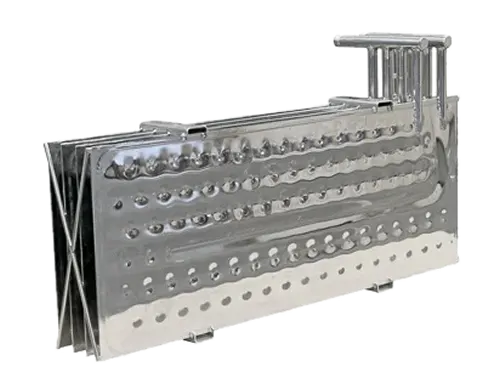

Embossed Plate:

Designed to be installed inside of tanks or production line

- Tanks

- Conveyor Lines

Tube-in-Tube:

Ideal for higher viscosity or fluids containing particulates.

- High Viscosity

- High Temperature & Pressure

- Temperature Crossing

Heat Transfer Solutions

Since our inception, we've focused on providing top-tier heat transfer solutions, with a particular focus on sanitary heat exchangers critical for industries where hygiene is paramount. Our expert engineers will guide you through the selection of the most suitable heat exchanger type for your application, including shell & tube, plate & frame, tube-in-tube, and embossed plate designs.

Each of these heat exchangers is designed to meet rigorous sanitation standards required in sectors such as food and beverage, pharmaceutical, and chemical processing. Shell & tube heat exchangers offer durable, high-pressure options, while plate & frame systems provide efficient heat transfer and ease of maintenance. Tube-in-tube heat exchangers are ideal for applications requiring special handling of the product, and our embossed plate models well suited for applications where traditional fluid processing is not available.

We offer both off-the-shelf and custom-engineered heat transfer solutions at competitive prices. Our mission is to assist you through every phase, from sizing and selection to production, ensuring that your heat exchanger exceeds expectations.

Common FAQs

- Food Grade Heat Exchangers

- Heat Exchangers in Dairy Industry

- RO Water Heat Exchangers

- WFI High Purity Heat Exchangers

- Sanitary Shell and Tube Heat Exchangers

- DI Water Stainless Steel Heat Exchangers

- Demineralized Water Heat Exchangers

- Cleaning in Place Plate Heat Exchangers

- Wine Must Heat Exchangers

- Heat Exchangers in Pharmaceutical Engineering

- 3A Sanitary Standard Heat Exchangers

- Sanitary Vapor Condensers

- Heat Exchangers for Wort Cooling

- Distillery and Brewing Heat Exchangers

- Biotech Sanitary Heat Exchangers

- Sanitary Plate and Frame Heat Exchangers

- Heat Exchanger for Milk Pasteurization

- CBD Extraction Machines

- Sterile Water Heat Exchangers

- Beverage Heat Exchangers

- Cannabis Heat Exchangers

- Sanitary Tube in Tube Heat Exchangers

- Heat Exchangers for Liquid Eggs

- Sanitary Evaporators

- Distillation Heat Exchangers

- Sanitary Embossed Plate Heat Exchangers