Heat Exhanger Distillation Column

Distillation heat exchangers are pivotal in industries like petrochemical, pharmaceutical, food and beverage, and environmental management, optimizing processes by improving energy utilization and reducing operational costs effectively. With decades of expertise, we ensure our heat exchangers meet the highest standards of performance, significantly enhancing the distillation process's energy efficiency and cost-effectiveness for our clients.

- Distillation Column: Distillation column heat exchangers are central to separating mixtures in continuous processes across critical distillation applications.

- Condensers: Condensers in distillation serve to cool vapor, transforming it back into liquid form for use in a variety of applications.

- Reboilers: Reboilers, as specialized distillation heat exchangers, play a crucial role in vaporizing liquids, integral to the distillation process efficiency and effectiveness.

- Pharmaceutical: In the pharmaceutical industry, distillation purifies chemicals, essential for creating safe, effective medications and ensuring regulatory compliance and quality control.

- Alcohol and Beverages: In the alcohol industry, distillation separates ethanol, enhancing purity and flavor, crucial for producing high-quality spirits with distinct characteristics.

- Perfumes In the perfume industry, distillation is key to extracting pure, aromatic essential oils, vital for creating fragrances with depth and complexity.

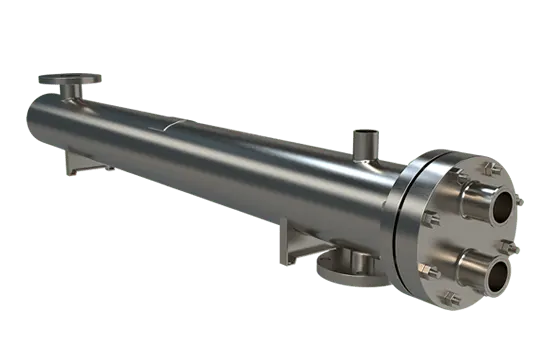

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Bio-Tech

Plate & Frame:

Sanitary Applications

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

Reboiler Heat Exchangers for Distillation and More

A reboiler, or reboiler heater, is a heat exchanger crucial for transferring heat to and from process fluids in chemical processes. It converts a process fluid into steam (vapor) or a steam-condensate mixture.

Reboilers in Distillation

Reboilers are primarily used to initiate the distillation process by heating the liquid at the bottom of a distillation column, sending it up as vapor. They are also applicable in other chemical processes. Typically, reboilers are shell and tube heat exchangers.

How Does a Reboiler Heater Work?

In distillation, a liquid mixture of various components is drawn into a reboiler for partial or full boiling. This produces vapor, which returns to the column to drive the distillation separation. Positioned at the base of the distillation column, the reboiler supplies heat, while the condenser at the top removes it.

Types of Reboilers

Various types of reboilers cater to different applications. We design and manufacture the following reboilers:

Kettle Reboilers

Heating fluid passes through tubes covered by the liquid needing distillation. The process results in vapors collected by the tower, while the liquid by-product is withdrawn.

Simple and reliable

Suitable for vacuum operation and high vaporization rates up to 80% of the feed

Fired Reboilers

These pressure vessels heat process fluids via tubes, requiring a pump to circulate the column liquid.

Low upfront cost

Simple maintenance

Cost-effective heating

Forced Recirculation Reboilers

Require a pump to circulate the liquid, useful for both once-through and recirculating flows. These can be located far from the main column.

Suitable for viscous and highly fouling fluids

Flexibility in reboiler location

Thermosyphon Reboilers

Available in vertical or horizontal types, these reboilers operate based on the density difference between liquid and vapor, eliminating the need for an external pump.

Economical with no pump required

Stab-in Bundle Reboilers

Also known as internal reboilers, these have a tube bundle inserted into the bottom of a distillation column, boiling off the liquid. Suitable for smaller duties due to column diameter limitations.

Reboiler Design Considerations

When selecting a reboiler heater, consider whether to vaporize on the shell or tube side, use gravity or forced flow, orient the unit vertically or horizontally, choose a flow-through or kettle design, or install baffles inside the tower.

With extensive experience in this sector, we work with you to design the optimal reboiler heat exchanger for your process, maximizing efficiency and performance.

Contact us to discuss your specific requirements and find the perfect reboiler solution for your application.