Distillation and Brewing Heat Exchangers

Heat Exchangers

The use of heat exchangers in breweries and distilleries allows for precise temperature control, which is critical during the mashing process where converting starches into sugars requires specific thermal conditions.

Wort Cooling

During the brewing of beer, wort (the liquid extracted from the mashing process) must be rapidly cooled before yeast can be added for fermentation. Plate heat exchangers are known for their high heat transfer efficiency and compact form factor, and are often employed in this step. They enable a fast and uniform cooling of the wort, preventing undesirable microbiological activity and ensuring the best conditions for yeast to thrive.

Subsequently the removal of unwanted proteins is achieved through carefully managed heat application, which is provided by heat transfer systems. After this, rapid cooling with heat exchangers is necessary to prepare the wort for fermentation, preventing the growth of bacteria and ensuring a clean start for yeast cultures.

Distillation

In distillation, the heat exchanger is equally important. The control of temperatures influences the separation of alcohol from the fermented liquid, directly affecting the purity and taste of the final spirit. The energy efficiency of heat exchangers, often using recovered heat from other stages of the process, reduces operational costs. Heat exchangers ultimately condense alcohol vapors back into liquid form, delivering purity and alcoholic strength with their exacting temperature control.

Industry-grade heat exchangers are designed to withstand the harsh working environment of breweries and distilleries, where acidic fermenting agents and high-temperature swings can take their toll on equipment. These exchangers' durability stands up to the caustic nature of cleaning chemicals, essential for maintaining hygiene standards without compromising the equipment's integrity.

In the world of brewery and distillery production, heat exchangers are more than just industrial equipment; they are central to the art and science of beverage production, affecting everything from efficiency and cost-effectiveness to the nuanced quality of the drink itself. Their value in heat management and energy recovery can't be overstated, making them indispensable tools in the beverage industry.

Precise Temperature Control

The chilling of finished products to stabilize and store them before bottling is another stage where heat exchangers play a key role. Advanced temperature changes performed by these exchangers ensure that beverages reach the needed stability without compromising their quality or flavor.

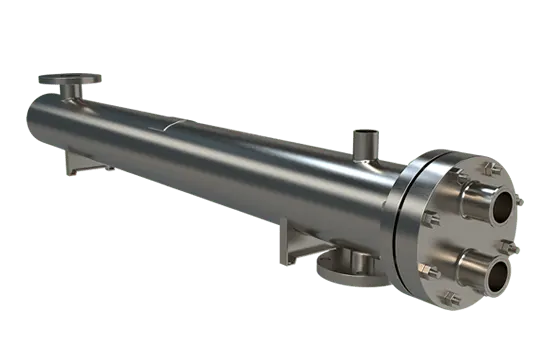

Shell & Tube:

Sanitary Applications

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Models

Plate & Frame:

Sanitary Applications

- Fully Customizable

- Multiple Materials Available

- Easy Service and Maintenance

Brazed Plate:

Sanitary Applications

- Compact Form Factor

- Multiple Materials Available

- Varous Connections

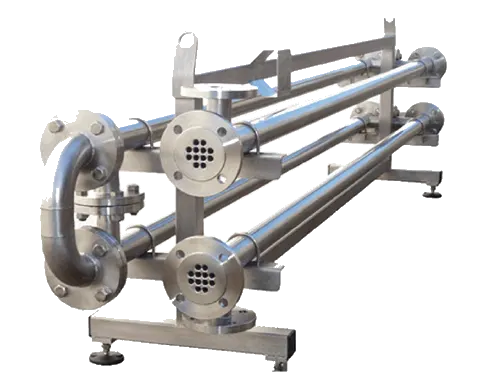

Tube-in-Tube:

Sanitary Applications

- Fully Customizable

- High Temperature & Pressure

- Temperature Crossing