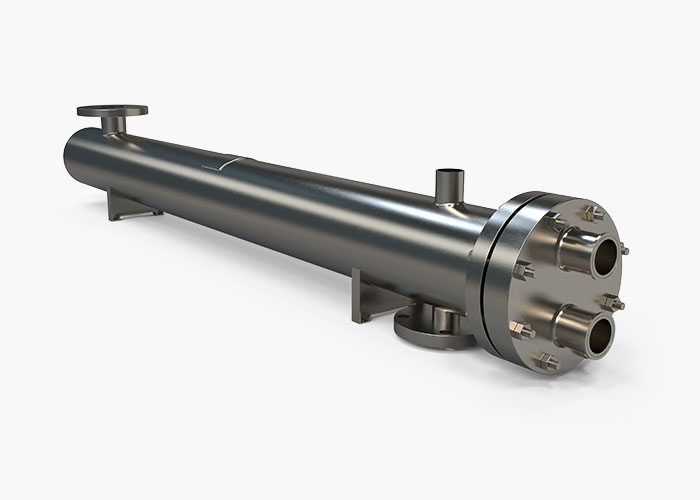

Sanitary Clean In Place Heat Exchangers

| APPLICATION | PRODUCT | STYLE | RATINGS |

|---|---|---|---|

| Steam-to-Water | Heat Exchanger | Shell & Tube | 150PSI / 375F |

Configuration & Size

Process:

Steam to Water

Construction:

Sanitary

Brand:

Enerquip

Materials of Construction

- Tubes: 304/316 Stainless Steel

- Tubesheet: 304/316 Stainless Steel

- Shell: 304/316 Stainless Steel

- Heads: 304/316 Stainless Steel

Clean In Place Sanitary Heat Exchangers

All CIP (Clean-In-Place) systems feature a configuration of one or more tanks designed to efficiently handle the cleaning process. Some systems use a single tank to combine the rinse and wash cycles. Others have two tanks, separating the rinse and wash processes to enhance efficiency. Certain CIP systems include a third tank dedicated to a recovery process, while others incorporate a fourth tank for storing alkaline, acid, or sanitizer solutions. Sanitary heat exchangers and other process equipment are often the target of these systems.

There are variations in CIP systems based on their operation: one-pass systems, which require precise chemical dosing, and multi-pass systems, which often require an extra tank to store alkaline, acid, or sanitizer—hence, the inclusion of a fourth tank.

Manufacturers have several options for distributing water and cleaning agents throughout the equipment. Spray balls are commonly used in systems where high water pressure isn't essential. For processes that demand highly pressurized water, rotary spray heads are preferred.

- Mechanical Cleaning: Modern food processing equipment, including heat exchangers, often includes cleaning-in-place (CIP) technology, which allows internal structures to be cleaned automatically with water and solvents (either acid or alkali). This method minimizes the risk of recontamination from manual cleaning.

- Manual Cleaning: Despite the effectiveness of CIP systems, manual cleaning and inspection are sometimes necessary. Heat exchangers may need to be disassembled to ensure all parts are thoroughly cleaned.

Regardless of the chosen method, ensuring that the entire surface area is thoroughly cleaned is critical. Ineffective design or insufficient components can leave areas untreated, leading to contamination and long-term operational issues.

Additional Considerations for CIP Systems

When designing or selecting a CIP system, consider the specific cleaning needs of your operation. Factors such as the type of soil, equipment design, and production schedule can influence the ideal configuration. It's also essential to regularly maintain and validate the CIP system to ensure it consistently meets hygiene standards. Integrating automated monitoring and control systems can enhance efficiency and reliability, reducing the risk of human error and ensuring thorough cleaning with each cycle.